Serie : 40

Identification : SUR, SURE

Type of construction : manual

with chain

Serie : 40

Identification : SUR, SURE

Type of construction : manual

with chain

Characteristics and application :

Shut-off gates are intended for an operational and emergency cutting-off of material flow from hopper-outlet, silos and similar equipment. They are not determined to regulation of material flow volume. They are appropriate for wide range of bulk, dry, powdered and granular materials with granulometric range 0 – 32 mm, in technological production lines of cement, lime, ground raw materials, aggregates of stones and similar products. The shut-off gates with manual wheels are used for a small percent occurrence of manipulations. The ones with chain wheel are used at high situated outlets.

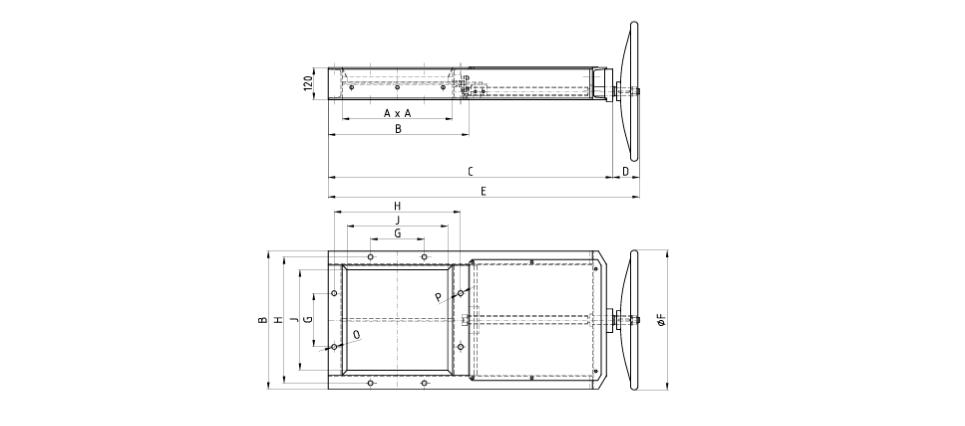

Dimensions and parameters :

Type range of shut-off gates includes 7 sizes < from 160 x 160 mm to 650 x 650 mm > ( s. tablet – project data sheet ), after technical-business discussion it is possible except these sizes to order a special modification.

Description of construction :

Shut off gate has usually square section, by atypical design it has a rectangular section (clear area). These sections are closed through plate-slide that is by SUR and SURE operated by means of nut and bolt with trapezoidal thread. The shut off gate frame is welded from U – steel section. The plate-slide, which is into the frame inserted, is supported through cylindrical boltheads. By the bigger sizes is the plate-slide supported through longitudinal support (in axis). Sheet of the plate-slide is sealed on the outlet from clear opening through adjustable packing. The clear opening is sealed between sheet and frame through packing cord (all over the circumference). The packing and sheet edges are protected with steel-squareends.

Used material :

Design of individual products is conditioned by physical properties of material, for which they´re determined. Shutting sheets are manufactured from steel class 11 or 17 acc. to CZ-Standard ČSN. For raw materials and products with temperature to 200°C we use seal profiles from special materials. Seating face of the plate-slide is solved otherwise by granular materials as by powdered materials.

Selection of customer references :

LASSELSBERGER, a.s. / Studénka – dry mortar and plaster mixtures

BAUMIT, spol. s r.o.. / Čakovice – dry mortar and plaster mixtures

KNAUF PRAHA a.s. – dry mortar and plaster mixtures

VÁPENKA VITOŠOV a.s. – dry mortar and plaster mixtures ground lime

SSP HLUČÍN s.r.o. – dry mortar and plaster mixtures

LOVOCHEMIE a.s. – powdery materials

RKZ a.s. / Keramička Rakovník – ceramic raw material „Makovec“

ALSTOM Power, s.r.o. Brno – fly-ash

KOFING a.s. – furnace additives

UNIPID TRADE spol. s r.o. – limestone

MONTÁŽE s.r.o. Trenčín – anode admixture

ENVEN a.s. – filter dust from filter dedusters

ENVIRMINE spol. s r.o. – power fly-ash

CEMDESIGN spol. s r.o. Trenčín, – cement

ZVVZ-ENVEN Milevsko a.s. – filter dust from filter dedusters

Gebrüder Lödige Maschinenbau GmbH – dry mortar and plaster mixtures, powdery materials