Serie : 43

Identification : TUP

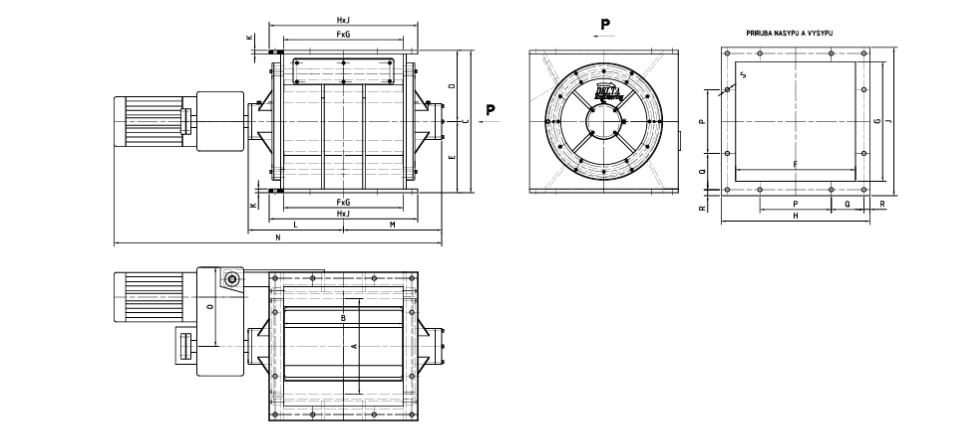

Type of construction : welded- 320-650

Serie : 43

Identification : TUP

Type of construction : welded- 320-650

Characteristics and application :

Rotary valve is intended for a fluent and regulated transportation or volumetric dosing of loose fine grained materials from bins, or it serves as closing and feeder at dedusting filters. Major decision criterion for using this equipment in technological line are characteristics of transported material. The material must be loose, non-adhesive and must not have arching tendecy. The graine size cannot be more than 5 mm, the max. allowable temperature of conveied material at valves with polytan planchettes is +80°C and with steel planchettes +150 ° Celsia. The application of rotary valve for another material must be before consulted with the producer.

Dimensions and parameters :

Type range of rotary valves contains 8 basic sizes derived from rotor diameter < 320 up to 650 mm > and rotor length, in the whole scale of rotor shaft rotation speed and corresponding capacity. The conveyers are delivered completely equipped, with drive, rotation indicator holder and incl. connecting material. After technical – commercial consulting it is possible to order some modifications or a special type of construction.

Description of construction :

Rotary valve is formed by welded casing equipped with anchoring flanges for upper inlet and down outlet of material. The front sides of casing are provided with the shield covers. In the casing of rotary valve there is pressed in the exchangeable insert. Rotor of rotary valve is fitted in two antifriction bearings mounted in the shield covers. These covers as well as the rotor are shifted in the exchangeable insert and fixed by the pressure flanges to the body of valve. The cells of rotor result from the spatial division inside of valve body by rotor ribs with exchangeable steel or polytan planchettes depending on temperature of transported material. Side sealing of rotor is solved by means of labyrinth on the circumference between the rotor, insert and shield cover. An accidental material outflow into bearings is prevented by means of adjustable sealing. The drive of rotary valve is realized by means of slip-on geared motor fixed to the rotor shaft by the clamping joint.

Used material :

Construction – rotary valve is made from a normal steel (class 11 acc. CZ-Standard ČSN) as a welded construction. The planchettes on rotor are made from POLYTAN, steel planchettes from HARDOX or BRINAR.

Selection of customer references :

LASSELSBERGER, a.s. / Studénka – dry mortar and plaster mixtures

BAUMIT, spol. s r.o.. / Čakovice – dry mortar and plaster mixtures

KNAUF PRAHA a.s. – dry mortar and plaster mixtures

VÁPENKA VITOŠOV a.s. – dry mortar and plaster mixtures ground lime

SSP HLUČÍN s.r.o. – dry mortar and plaster mixtures

ALSTOM Power, s.r.o. Brno – fly-ash

ENVEN a.s. – filter dust from filter dedusters

CEMENT HRANICE a.s. – cement dry mortar and plaster mixtures

ENVIRMINE spol. s r.o. – power fly-ash

ČMC a.s. / vápenka Mokrá – dry hydrate

VÍTKOVICE a.s. – power fly-ash

INTOCAST KOŠICE a.s. – magnesite filter dust

LOVOCHEMIE a.s. – powdery materials

RKZ a.s. / Keramička Rakovník – ceramic raw material „Makovec“

SILOsystém s.r.o. ¬– plaster mixtures

ČMC a.s. / cementárna Králův Dvůr – cement

PSP ENGINEERING a.s. – dry hydrate

ČEZ a.s. / elektrárna Dětmarovice – power fly-ash

ŠKO-ENERGO spol. s.r.o – fly-ash

LHODOL s.r.o. , Dolkam Šuja / SK – lime

Schenckprocess Slovakia spol. s r.o. – fly-ash

CEMDESIGN spol. s r.o. Trenčín, – cement

ZVVZ-ENVEN Milevsko a.s. – filter dust from filter dedusters

Gebrüder Lödige Maschinenbau GmbH – dry mortar and plaster mixtures, powdery materials

EXEMPLA, s. r.o. – lime