Serie : 52

Identification : VSV

Type of construction : motor controlled

Serie : 52

Identification : VSV

Type of construction : motor controlled

Characteristics and applications :

Roll bottom dischargers (VSV) - serve for flow distribution of dry, fine grained material in pneumatic transportation ways to longitudinal way or vertically down, facing the flow of material. The equipment is dustproof and is intended for installation in technological lines, especially in building material industry. Temperature of transported material up to +80°C.

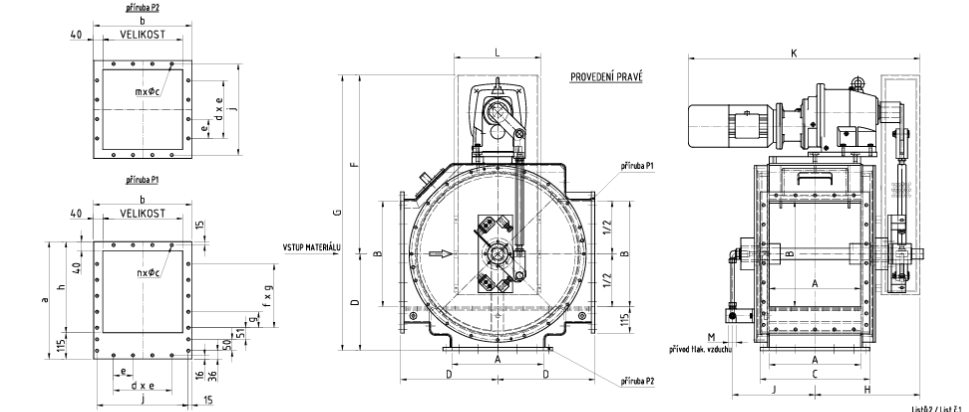

Dimensions and parameters :

Type range of roll bottom dischargers is designed in 8 basic sizes < 150x150 up to 650x650 mm > (see tablet on data sheet). The clear opening (see tablet) is decisive for using in transporting way. Control of inside roll is ensured by means of electrical drive with brake. Delivered VSV are equipped with electrical elements from prestigious suppliers acc. to recommendation of producer, alternatively acc. to wish of customer.

Description of construction :

Roll bottom dischargers has rectangular inlet and outlet for horizontal and vertical direction (connecting to pneumatic fluide slide) and a square bottom outlet (connecting to discharge chute). Inside roll (cylinder) ensures material flow distribution to separate branches and it has an aerated bottom. This roll is fitted in with shaft into body and outside covers of VSV. The covers are bolted on body flange of VSV. Inside roll operating ensures motor drive equipped with a brake, which is bolted on anchoring plate at the VBV-body. Leverage from drive onto inside roll has a cover and there is a flow direction arrow on it. One of side covers is equipped with screw connection for compressed air.

Used material :

Construction – body of VSV is welded with inlet- and outlet- flange. Material flow regulating ensures welded inside roll with clear opening and shutting surface. The roll is fitted through journals into self-lubricating sleeves on out side covers of VSV. The inside roll, journal fitting and outside covers are equipped with sealings to prevent dustiness. In accordance with placing of drive we have right- and left- design.

Selection of customer references :

ALSTOM Power, s.r.o. Brno – fly-ash

KOFING a.s. – furnace additives

Gebrüder Lödige Maschinenbau GmbH – dry mortar and plaster mixtures, powdery materials

RAKO a.s. – limestone

OMYA a.s. – limestone

BOCHEMIE s.r.o. – chloramine

CEMDESIGN spol. s r.o. Trenčín, – cement

CEMMAC / cement. Horné Srnie / SR – cement

D.D. Fabrika CEMENTA LUKAVAC (a.s.) – cement

VÁPENKA ČERTOVY SCHODY a.s. – lime

POVÁŽSKÁ CEM. LADCE s.r.o. / SR – cement , clinker, slag

HOLCIM a.s. / cementárna Prachovice – cement

ABENDIA,s.r.o. – multipowder