Serie : 33

Identification : PSO

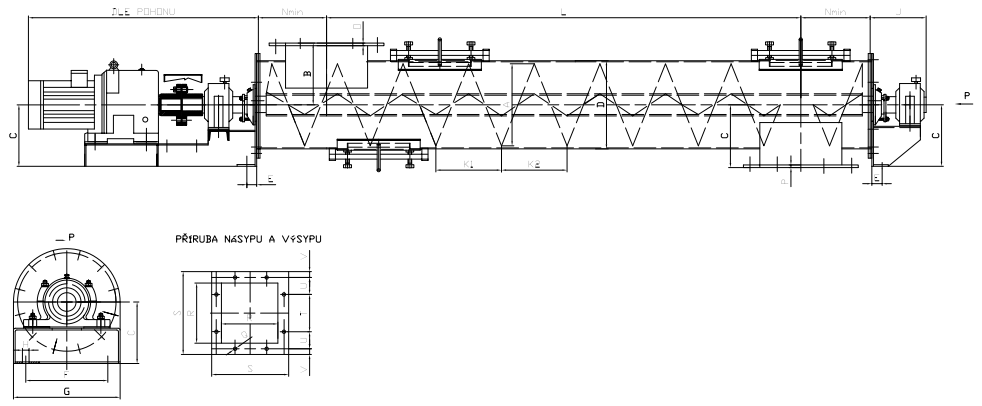

Type of construction : tube

Serie : 33

Identification : PSO

Type of construction : tube

Charakteristics and appliacations :

Tube screw conveyer is intended for a fluent and regulated transportation or volumetric dosing of loose fine grained materials from bins. Major decision criterion for using this equipment in technological line are characteristics of transported material. The material must be loose, non-adhesive and must not have arching tendecy. The graine size cannot be more than 10 mm, the max. allowable temperature of conveied material is +150 ° Celsia. The application of screw feeder for another material must be before consulted with the producer.

Dimensions and parameters :

Type range of tube srew conveyers contains 9 basic sizes derived from helix diameter < 135 up to 630 mm >, in the whole scale of screw shaft rotation speed and corresponding capacity. Transport length can be chosen between 1.000 – 6000 mm.

The conveyers are delivered completely equipped, with drive, rotation indicator, incl. connecting material. After technical – commercial consulting it is possible to order some modifications or a special type of construction.

Description of construction:

Tube screw conveyer consists of tube trough, which is shut on both ends (sites) with shields. Parts of these shields are ball bearings with special packings of worm shaft, too. The trough has a removable coverings with inspection openings. The worm shaft with a progressive helix is positioned on bearings outside of trough. At longer conveyers are used an adjustable hanging bearings. Inlet and outlet flange are delivered extra to be welded on the building site or are welded already at the assembly in workshop. The drive of screw conveyer is made in a few ways: a standard construction with gear box, which is via elastic clutch connected with screw shaft, further alternatives are chain gear or slip-on gear box.

Used material :

Construction – tube screw conveyer is made from a normal steel (class 11 acc. CZ-Standard ČSN) as a welded construction. Screw windings are pressed singly and are made from a normal/carbon steel (class 11 acc. CZ-Standard ČSN). On special requirement the windings can be made from material HARDOX or with hard surfacing (welded-on).

Selection of customer references:

LASSELSBERGER, a.s. / Studénka – dry mortar and plaster mixtures

BAUMIT, spol. s r.o.. / Čakovice – dry mortar and plaster mixtures

KNAUF PRAHA a.s. – dry mortar and plaster mixtures

VÁPENKA VITOŠOV a.s. – dry mortar and plaster mixtures ground lime

SSP HLUČÍN s.r.o. – dry mortar and plaster mixtures

ROCKWOOL INTERNATIONAL a.s. – insulation material

ALSTOM Power, s.r.o. Brno – fly-ash

A.J.KŐLLEMANN GmbH – chemical products

Gebrüder Lödige Maschinenbau GmbH – dry mortar and plaster mixtures, powdery materials

M-TEC / SRN ¬– dry mortar and plaster mixtures

ENVEN a.s. – filter dust from filter dedusters

CEMENT HRANICE a.s. – cement, clinker

dry mortar and plaster mixtures

ENVIRMINE spol. s r.o. – power fly-ash

ČMC a.s. / vápenka Mokrá – dry hydrate

SATEC PRAHA s.r.o. – power fly-ash

VÍTKOVICE a.s. – power fly-ash

INTOCAST KOŠICE a.s. – magnesite filter dust

ČEZ a.s. / elektrárna Dětmarovice – power fly-ash

PORFIX a.s. / Zemianské Kostolany – cement, fly-ash

VÁPENKA ČERTOVY SCHODY a.s. – lime

POVÁŽSKÁ CEM. LADCE s.r.o. / SR – cement , clinker, slag

ZVVZ-ENVEN Milevsko a.s. – filter dust from filter dedusters

UNIPID TRADE spol. s r.o. – sand, cement