Serie : 44

Identification : KKP

Type of construction :pneumatic operated

Serie : 44

Identification : KKP

Type of construction :pneumatic operated

Charakteristics and application :

Branching chute – serves for regulation of material flow into separatel technological branches. It is determined for bulk and granular materials with grain size within the range 0 – 40 mm (sporadic graine size max. 50 mm). Allowable humidity of powdered materials – water content max. 1% at temperature above 0°C. At granular materials with clay content is allowable water content max. 3%. Temperature of transported material: dry materials – from -30° to +100°C, humid materials – from 0°to +100°C.

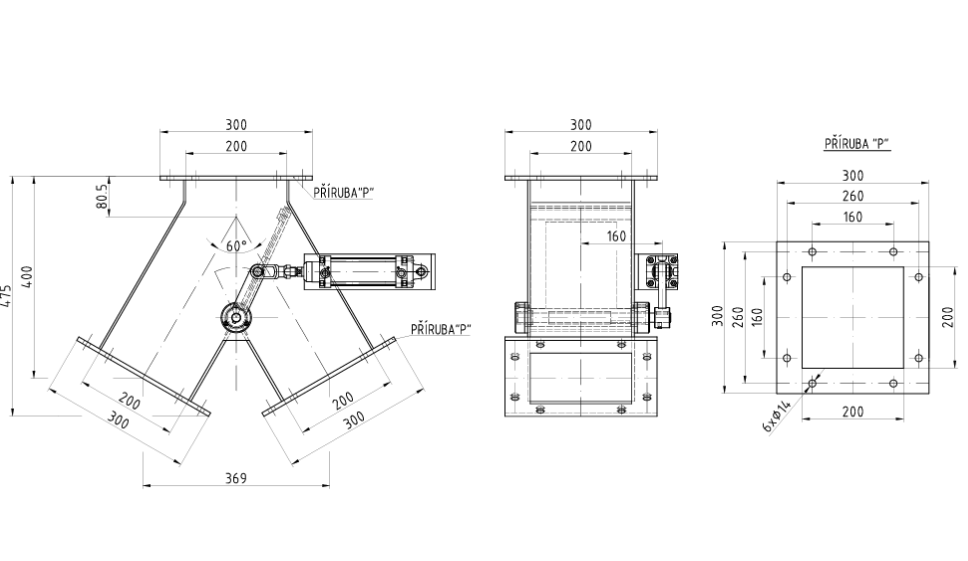

Dimensions and parameters :

Type range of branching chutes KKP is delivered in as a special type of construction, but It has to be agreed on technical-business discussion. We design for operating of individual sizes suited pneumatic cylinders. The supplied branching chutes have pneumatic components from prestigious producers. These components are designed by producer, alternatively in accordance with order or with agreement with customer.

Description of construction :

Branching chutes are designed for mounting into gravitational chutes. These chutes have square or rectangular cross section, which is determined to regulation of material flow into two technological lines. Operating is ensured through a pneumatic cylinder , which has a corresponding twist moment. It is ensured an end position-signalling, too. Outlet flanches form an angle 60° or other angle, if need.

Used material :

Construction – the body of branching chute has welded construction with an inlet flange and two outlet flanges, that have square or rectangular shape. We can use an armouring of body-inside walls. This armouring corresponds to sort of transported material. The flow regulation of transported material is ensured with an inside plate with an armoured slide-surface. Chute-sheet is fixed through shaft into the bearings (friction or antifriction bearings), which are placed outside of the chute. Shaft support is equipped with sealing to prevent dust nuisance.

Selection of customer references :

ALSTOM Power, s.r.o. Brno – fly-ash

KOFING a.s. – furnace additives

UNIPID TRADE spol. s r.o. – limestone

ZMOP spol. s r.o. – limestone

PITTSBURGH Corning CR s.r.o. – cullet

POVÁŽSKÁ CEM. LADCE s.r.o. / SR – cement , clinker, slag

MONTÁŽE s.r.o. Trenčín – anode admixture

ENVEN a.s. – filter dust from filter dedusters